Sustainable Timber Drying

Energy Savings

Energy efficiency is the key to a sustainable business going into the new millennium; to be frank, all types of Solarola drying systems boast an array of energy-saving features that make conventional and alternative solar drying technologies seem like relics of the industrial era. And we don’t say that lightly – here are the facts:

Independent tests have proven that solarola can produce and deliver more than the same amount of heat energy in a one-week drying cycle as others can deliver in a month! (Refer Case Study- D Fir)

Drying materials, including timber consume massive amounts of energy and contributes massively to our global greenhouse gas emissions. Using Solarkilns advanced drying technology in Melbourne-Australia, a leading company has proven that it has reduced heat energy consumption by 81% over its past full year of operation. Independent audit reports are available to prove that solarola kilns are capable of delivering many times the solar energy that other solar kiln technologies are capable of. Solarola has reduced time compared to conventional drying technology and always with markedly superior quality outcomes.

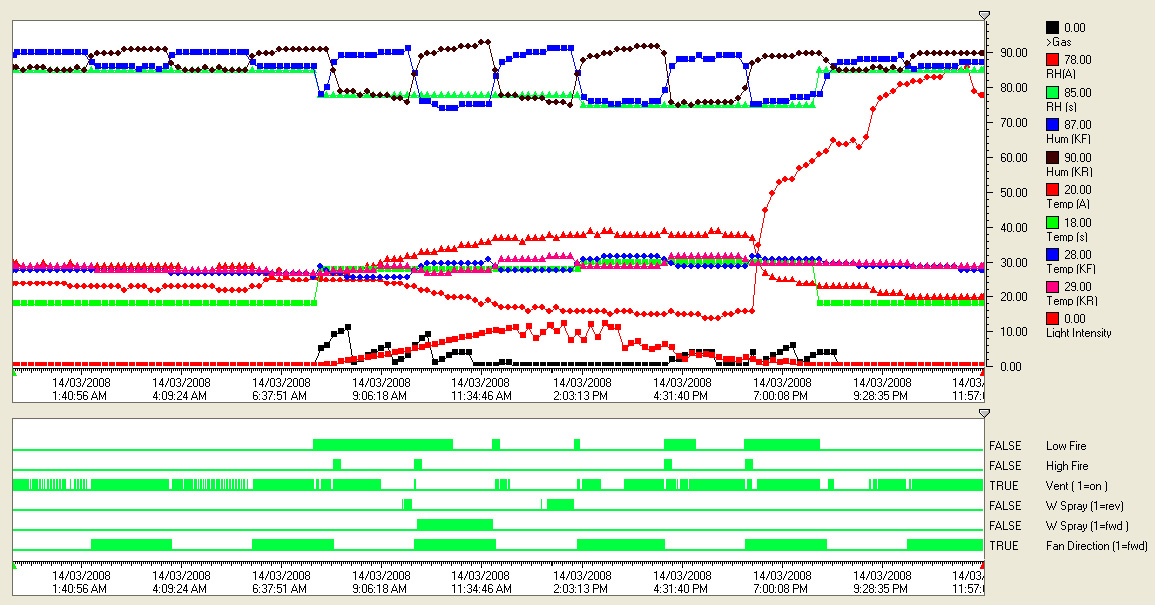

Note 30deg c lift in kiln temperature and excellent control of upper limit 60deg kiln control setting.

Drying a range of timber species from green to 12% moisture content over a full year of operation, Enviro-Forest Solutions Ltd has achieved heat energy efficiency inputs in the range of 0.5 to 1.6 gj/M3 of dried timber. Average consumption was 1.1 gj/M3. Compared to conventional drying in medium-high temperature kilns (6.2 gj/M3) this is a massive saving and energy efficiency advantage for the company AND for the environment.

Melbourne’s winter climate conditions are cold with solar intensity contributions almost negligible on the worst days. In optimal solar environments and most warm tropical environments, the energy efficiency and savings using Solarkilns advanced technology are even greater. For solarola kilns, many parts of South America (especially central Brazil) do not require supplementary heating units to dry as fast as conventional ones.

In warmer environments, supplementary heaters are not required at all. So that’s 100% solar energy, being used to dry timber all year round at high speeds consistent with other drying technologies.

Other favourable energy efficiency advantages exist for solar kilns technology. Circulation air fans are the second key element of energy consumption in most drying systems. Electrical energy consumption at our Melbourne test site has been only 20-25% of that used by conventional drying systems.

Solarkilns advanced cyclic drying control systems accommodate automated cooling and heating cycles around the daily solar energy cycle. Electric fans automatically slow the speed and current to draw and conserve energy consumption at night, relieving stress in a superior fashion compared to conventional drying. Not only does this allow for an overall faster process time, but it also saves even more energy.

Anyone in the timber industry is all too aware that drying is one of the biggest costs in the overall timber manufacturing cycle. So if you’re looking to dramatically cut costs in your operation, improve your quality, yield and value outcomes AND reduce your environmental impact, Solar Kilns’ Solarola kilns are the only real drying technology solution for anybody serious about energy efficiency.

Our superior energy efficiency produces tremendous overall cost reductions given that energy costs typically account for 30% to 60% of the total drying process cost and up to 60% of the energy required to convert logs to dry-sawn timber. But the savings don’t stop there.

The structural materials used to build Solarkiln dryers are less than half that of a conventional kiln. Energy costs consumed to manufacture the materials are lower than others. Despite having more sophisticated control systems to deal with weather variables, the lower cost structure generally combines to produce a lower overall purchase price option compared to other well-controlled kiln dryer options. Because Solarkilns have less thermal mass in materials to heat during the drying process, the energy efficiency of Solarkilns technology is enhanced.

Solarola kilns also require fewer maintenance inputs than conventional kilns exposed to acidic timber drying environments. Why? Well, plastic doesn’t rust in acid environments, nor does aluminium. The plastic skin doesn’t delaminate like Styrofoam laminated panels, and the mortar doesn’t fall out due to extreme conditions.

No longer do greenhouse-type dryers generally need to be regarded as inferior to conventionally insulated styrofoam-clad kiln enclosures. The insulation properties of our unique triple-skin cladding are second-to-none in terms of energy efficiency. At night and during cloudy periods, the control system automatically stops circulating air over the solar collector sheet, creating a second double-insulator air cavity that greatly reduces heat loss. The same “stall” feature causes a very small amount of heat loss to power a dehumidifier process between the plastic outer covers so that condensate ultimately gravitates outside the chamber to ground run-off points- avoiding the need to re-evaporate it internally. This is just one other unique feature of Solarkilns enviable energy efficiency.

Given all these features is it clear and easy to demonstrate that the collective advantages of the Solarola system are massive in terms of overall cost reduction and sheer energy efficiency. In fact, the Solarkilns drying system can pay for itself in a few years on comparative energy input savings alone.

Anyone in the timber industry is all too aware that drying is one of the biggest costs in the overall timber manufacturing cycle. So if you’re looking to dramatically cut costs in your operation, improve your quality, yield and value outcomes AND reduce your environmental impact, Solar Kilns’ Solarola kilns are the only real drying technology solution for anybody serious about energy efficiency.

Revolutionary & Environmentally Friendly

Using The Suns Energy To Heat The Kiln, Still Got More Questions?