Welcome

Solarkilns design is extremally effective at converting the suns energy into directly heating the kiln. A revolutionary, environmentally friendly drying system developed and proven in the timber industry with wide ranging applications where product drying and dehydration is required.

Industries Solarkilns can help with are:

- Agricultural / Food Products

- Sludge / Waste Products Dehydration

- Minerals / Hydroscopic Salts Final Drying

Solar Collection

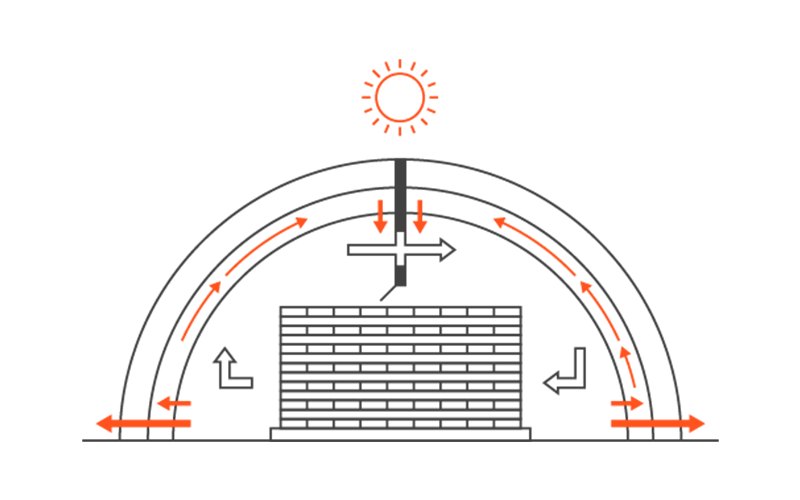

Principle of operation

Solarkilns dome kiln design makes the most out of daylight hours energy absorption. The dome shape is installed in a North/South alignment providing a large surface area facing the sun’s direction from sunrise to sunset. Whenever sunshine is on the kiln, solar energy is being absorbed into the kiln.

The kilns advanced control system works in harmony with day/night cycles and automatically adjusts the operation of the kiln to make the most out of cloudy days where intermittent sunshine is available. In fact, the control system even knows when a cloud blocks out the sun and adjusts to suit as you can see here.

2. Baffle

3. Timber stack or other product

4. Insulation layer

6. Solar airflow fans

7. Smart venting

8. Dryer airflow

Daylight Mode

Energy Absorbtion

Airflow through the inner cavity transfers re-heated air in to the kiln

Reversing main circulation fans distribute heated air during the solar heating phase

Night Time / Cloud Stall Mode

Energy Conservation

Air flow through inner air space stops

Outer and inner air spaces act as efficient dual insulation layers

Reduced air flow within kiln

High humidity treatment period and heat storage

Revolutionary

Environmentally Friendly

Technology

Our Solarkilns have had over 25 years of development to be able to offer the user the many benefits of solar heating and the advantages of a superior faster proven cyclic drying method

Case Studies

Some of the species commonly dried by our solar kilns are

Good News For You and the Enviroment

The lightweight construction makes solar kilns very economic to purchase, and inexpensive to erect on site. In locations where solar contribution is optimal, kiln operation can be programmed t operate on solar only for the required thermal energy input into the kiln. Alternatively, a hybrid combination of solar thermal energy and auxiliary heating can be used. Auxiliary heating methods available such as LPG, Natural Gas, steam, hot water, heat recovery and many other options.

Another saving for both the hip-pocket and the environment is a typical ‘Solarola’ technology Solar Kiln. Working in moderate climate zones, producing energy savings valued at approximately 4-6 times their upfront cost over a ten-year life span. Now that’s good karma!

Client Testimonials

What Our Clients Have To Say About Solarkilns

We would like to extend our appreciation for supplying us with an excellent product and a level of service well beyond our expectations.

As a producer of 100% reclaimed Teak products approved by the Forestry Stewardship Council, your Solarkiln technology has provided a very effective and environmentally responsible solution for our manufacturing operation in Indonesia. The system achieves a per unit running cost second to no other conventional kiln we have seen. This made it the clear choice according to our environmental and financial objectives.

To maximise the use of our resources, our operation also requires we have very little timber wasteage. Where degraded stock can be prevalent with less sophisticated conventional drying schedules, the Solarkiln’s advanced cyclic drying system has proven to be a success. The quality of drying has been exceptional.

We would also like to express our gratitude for passing on a wealth of knowledge and information. Combined with very cleverly automated system, your direction has given the very least experienced of operators the ability to achieve excellent drying outcomes. The remote support has been very successful and your invaluable input has ensured we are realising the full extent of this technology and will continue to do so in the future.

Congratulations on an outstanding product!

Cost Effective

In most cases, the deliverable additional savings each year due to unique features of this technology will pay for the kiln

Find out how our affordable Kiln Technology can benefit your business