Whenever sunshine is on the kiln, free solar heating is being absorbed into the kiln

Solarkilns’ Solarola Technology: A Revolution For The Timber Industry

Solarkilns’ Solarola technology enables an efficient and superior method of drying a large range of timber species through its’ advanced solar drying technology. The Solarola kiln system has a unique cyclic-drying method which capitalizes on the daily cycles of heating and cooling that naturally occur each day. This system has now been proven to significantly reduce cracking, splitting, warping, case hardening and collapse commonly found in many difficult to dry timber species, in both softwood and hardwood. Solarkilns can also reduce thermal energy costs by as much as 100% whilst still drying as fast as a fuel heated kiln by operating on solar contribution alone for it’s thermal heat requirements. With seasonal fluctuations, the operation of any supplementary heating system for the kiln becomes a choice at the discretion of the kiln operator/owner.

Solarkilns Technology For Drying Fruits, Spices, Foodstuffs and Many Other Products That Require Dehydration

Primarily developed for the timber industry, the same drying technology benefits can be applied to drying many other products such as fruit, herbs, spices, leaves and many other edible and waste products. Accurate control in the Solarkilns chamber of humidity and temperature allow sensitive products to be dried with optimal control during critical stages of the drying process which can eliminate degraded product. Talk to Solarkilns about your application and how our system can benefit your drying operation.

T2 & T3 Solarkilns 50-300 cubic meter capacity – ideal for medium to larger sawmill operations

This T3 kiln has a capacity of 150 cubic meters with auxiliary LPG heating system- Hardwood Timber drying – location Northern NSW, Australia.

T3 kilns x 2, for scale note the 20ft shipping container used as a control room

MiniPro Solarkilns (16 and 20 Cubic Meter Capacity)

Ideal for:

- Portable sawmill owners/operators

- R&D facilities

- Educational organisations

- And to prove drying of your timber in your location prior to larger capital expenditure.

The MiniPro is available in two lengths, 6.1 meters and 7.5 meters. (7.5 meters long unit shown in photo, capacity based on 2″ timber thickness)

The MiniPro timber drying kiln is an excellent and vastly superior alternative to a converted shipping container timber drying kiln. Where a 20ft container can hold 6-8 cubic meters of timber the MiniPro kilns are sized at 16 & 20 cubic meters capacity. With prices starting at USD$20,000.00 for the 6.1 meter long unit & $22,500.00 USD or the 7.5 meter unit. These kilns are supplied as a kit with all assembly instructions provided. Go to the Contact Us page to submit a request for further information on how a MiniPro can benefit your timber drying needs.

Principle of Operation

Solarkilns dome kiln design makes the most out of daylight hours energy absorption. The dome shape is installed in a North/South alignment providing a large surface area facing the sun’s direction from sunrise to sunset. Whenever sunshine is on the kiln, solar energy is being absorbed into the kiln.

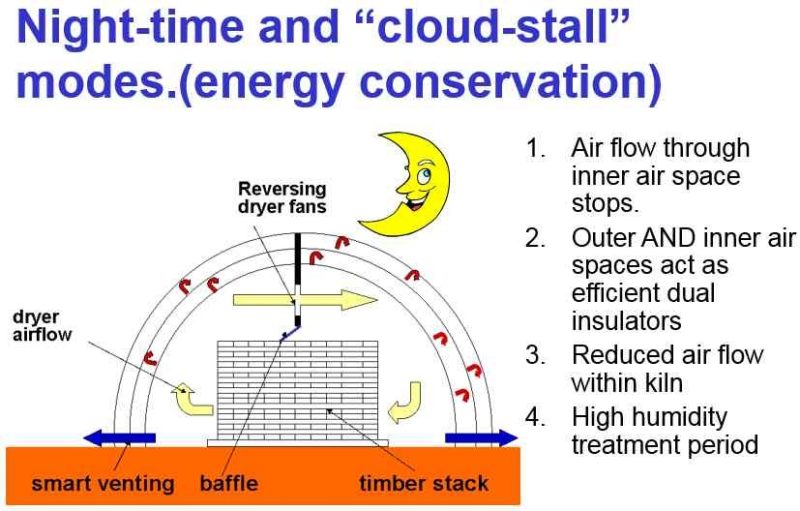

The kilns advanced control system works in harmony with day/night cycles and automatically adjusts the operation of the kiln to make the most out of cloudy days where intermittent sunshine is available. In fact, the control system even knows when a cloud blocks out the sun and adjusts to suit as illustrated below.

Loading Timber into a Solarola Kiln

Unlike traditional timber drying kilns which are permanent fixed structures into which timber stacks have to be loaded and unloaded using a forklift, often driving in and out of the kiln multiple times with timber stacks at height. Solarkilns are loaded by rolling the kiln over the timber stack. This concept has some major advantages:

- Potential damage to the kiln by forklift operators lifting wide loads of timber is eliminated.

- Whilst the kiln is finishing a load, the next load of timber can be prepared and placed in position ready (next to the kiln, position 2)

- Only takes 1-2 men, 30 minutes to change over kiln position and be back up and running (absolute minimal downtime)

- The next load of timber can be accumulated in position and be kept covered (green off the saw) or pre-air dry prior to kiln drying.

Solarola kiln on guide rails being positioned over a new load of timber.

Minimal downtime!

Solarkilns unique design provides large capacity chamber sizes at very economical prices per cubic meter capacity.

The only cyclically-controlled, commercial drying system in the world, our solar kiln has benefits that ensure maximum productivity with minimum cost.

- Light weight construction and simple assembly on site

- Energy efficient

- Protects enviroment by reducing carbon emissions

- Extensive savings in operation

- Ongoing enviromental benifits

Revolutionary & Environmentally Friendly

Using The Suns Energy To Heat The Kiln, Genius!

Still Got More Questions?