Cyclic drying should have been commercialised many years ago, such is its simplicity and superior outcomes. Often it’s the simplest and most natural way of doing things that solve the most vexing problems. Solarkilns have developed a unique and highly functional automated control system and a superior solar hybrid drying kiln that makes high level cyclic drying possible.

Basically speaking, cyclic drying refers to a kiln drying prescription that captures the positive and natural aspects of daily/seasonal conditions and conventional drying practices to produce an environmentally freindly method of operation. The cyclic concept has been around for many years in various simple forms. Now combining our Solarkiln technology with Cyclic operation the enviromental benifits are obvious.

The solarkilns cyclic drying process encourages regular highly regulated heating and cooling periods (phases) during the drying cycle, yet it cosistantly produces high quality dry wood within the same time frame as conventional drying methods. Our research activities have proven in many cases that faster drying times (than conventional kiln technologies can be achieved) are possible for many timber species. The dynamics are the same for drying many other products.

The intermittent heating and cooling cycles allow our cyclic drying method to regularly re-hydrate the driest parts of timber in such a way as to almost completely avoid the cracking, splitting and warping that is common to conventional drying. The method has been proven to greatly reducecase-hardening, a problem for almost all materials and organic products during drying.

One of the most important elements of successful drying is moisture differential (the difference in moisture between the inner core and outer case of individual boards). Achieving the correct moisture differential is fundamental because when the outer surface of wood is dried more quickly than the core, the outer surface may shrink at a greater rate than the core and in some cases can directly cause costly splits and cracks. These are inevitable consequences of conventionally heating and drying wood from the surface, of regularly increasing temperature and not providing balancing conditions; stress and degrade occurs even when conventional kiln drying is done well.

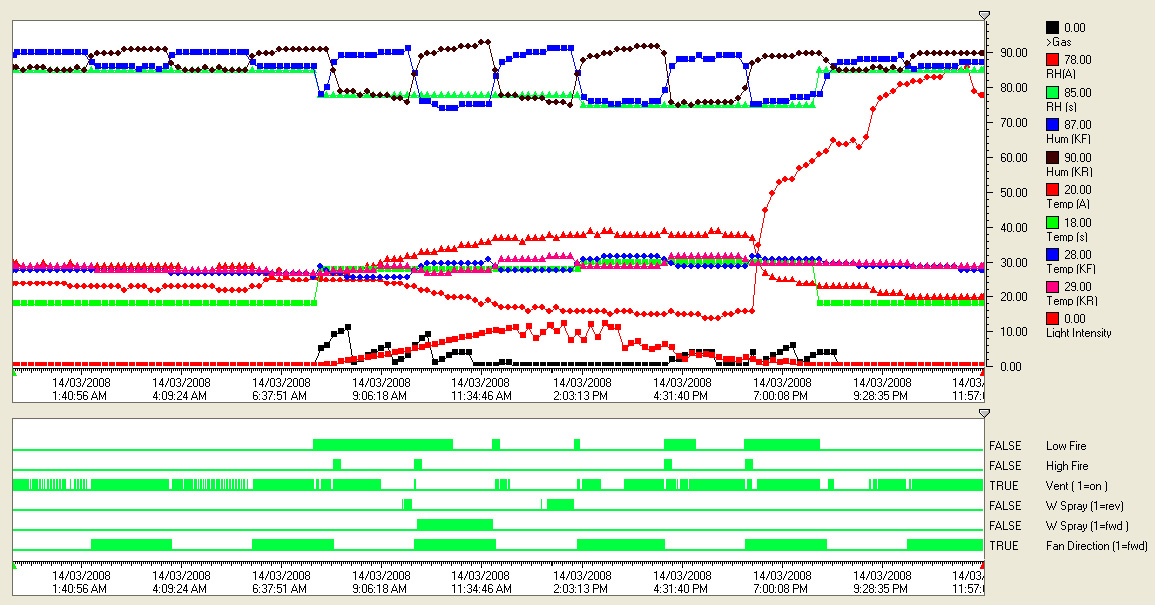

Graph Cyclic Drying Example Daily Data Snapshot

Heating and cooling cycles evident.

A proven success by solarkilns – the world leaders in this revolutionary innovation!

The implications of the cyclic drying system have important flow-on effects that go well beyond the huge advantage of producing more usable timber from raw stock. The future implications of our findings on the global lumber industry are substantial; not only for solar or hybrid kilns like ours, but also low-medium temperature kilns in general

When the technique of cyclic drying is added to the revolutionary and patented technology of the Solarola kilns, the result is an enviromentally freindly system for timber drying that can be applied to many other products.

Revolutionary & Environmentally Friendly

Using The Suns Energy To Heat The Kiln, Genius!

Still Got More Questions?